Product Information

Multi-layered bolus

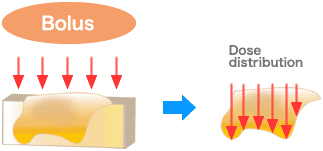

A range-compensation filter constructed from plastic for each proton beam plays a crucial role in forming the treatment volume corresponding to the targeted tumor profile.

Based on the bolus shape defined during therapy planning, 3 mm thick plates of bolus material are punch-pressed at high speed. After inspection of the shape, these plates are placed in a dedicated case and formed into a bolus block.

Product Features

The bolus is divided into 3 mm thick plates and processed by a high-precision turret punch press machine. The bolus is then optically inspected to achieve an overall processing accuracy of < 1 mm.

Processing the maximum target volume bolus (200 · 150 · 195 mm) takes no longer than 1 hour and less than 30 minutes for a standard size bolus.

The punching process suppresses burr formation and requires no deburring after processing. The block manufacturing method also automates the flow of processing and inspection and simplifies the entire manufacturing process.

Turret punch press

The bolus material plate is punch pressed with a regular die. The punch-pressed plates are multi-layered and placed onto the bolus case.

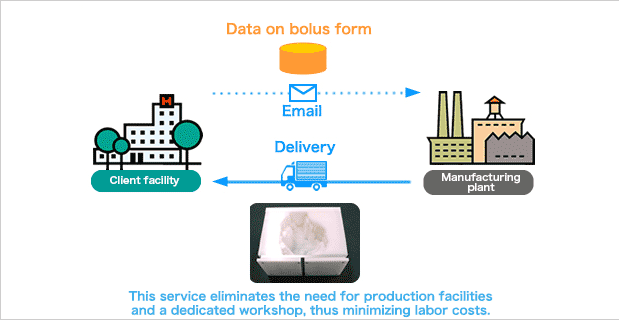

Bolus delivery service

APEX Medical, Inc.

KuramaeMyouken-ya Building 5F,3-17-4,Kuramae,

Taito-city Tokyo,111-0051,Japan

Phone:81-3-5829-4211 Fax:81-3-5829-4212

|Home |Product Information |Corporate overview |Inquiry |Links |Sitemap|

Copyright © 2010 APEX Medical, Inc. All Rights Reserved.